customized your Stainless Steel Product

- Customized Stainless Steel Product Process Flow

- 1. Inquiry & Design Consultation

- Customer submits concept, drawing, or sample.

- Engineering team reviews feasibility, material grade (e.g. SUS304, SUS316), and surface finish requirements (e.g. mirror, brushed, hairline).

- Provide initial quotation and lead time estimation.

- 2. Technical Drawing & Approval

- Create 2D/3D CAD drawings or prototype sketch based on client’s concept.

- Confirm dimensions, tolerances, and structure.

- Client reviews and approves final technical drawing before tooling or sampling.

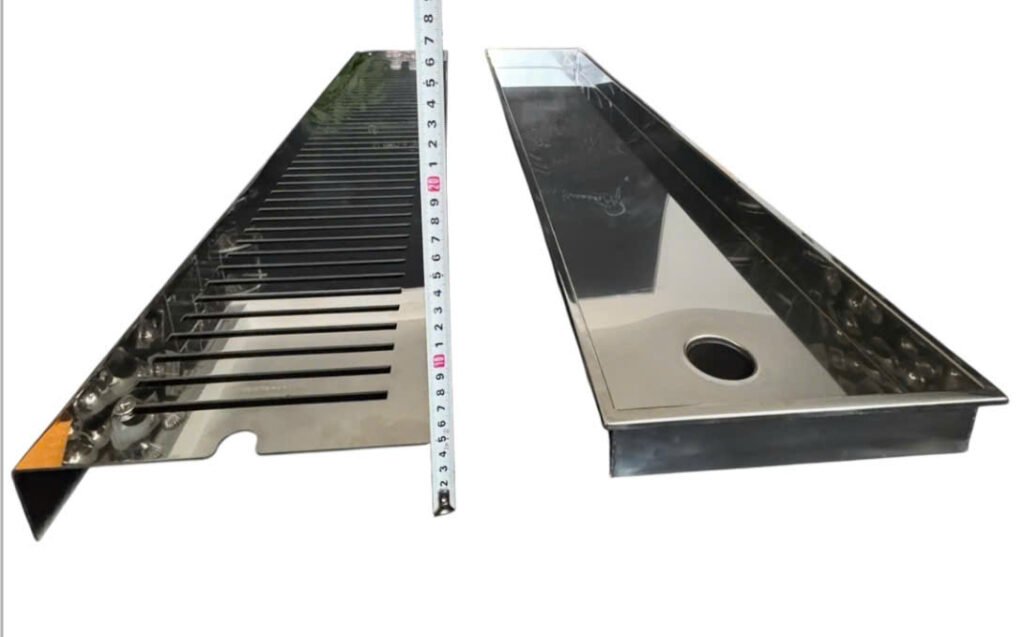

- 3. Material Selection & Cutting

- Select suitable stainless steel sheet, tube, or rod (based on thickness & grade).

- Use laser cutting / shearing / pipe cutting to prepare material to size.

- Mark parts with identification codes for tracking.

- 4. Forming & Fabrication

- Depending on product type, this stage may include:

- Stamping / Deep Drawing — for formed components (e.g. trays, covers).

- Bending / Rolling / Tube Forming — for brackets, pipes, frames.

- Punching / CNC machining — for holes or precise slots.

- 5. Welding & Assembly

- Use TIG / MIG / Spot welding according to product requirements.

- Check joint alignment and structural integrity.

- Assemble modular parts (e.g. base + cover + fittings).

- 6. Surface Treatment

- Grinding & Polishing to remove weld marks and smooth edges.

- Hairline / Brushed / Mirror finish applied per customer request.

- Optional passivation / anti-fingerprint coating for corrosion resistance.

- 7. Quality Inspection

- Inspect dimensions, surface finish, and weld quality.

- Apply QC checklists for each production stage.

- Conduct functional tests (e.g. load test, water leakage test).

- 8. Packaging & Shipping

- Apply protective film or foam to prevent scratches.

- Pack in custom cartons or wooden crates with labels and serial codes.

- Arrange shipment & export documents (CO, Invoice, Packing List).

- 9. After-Sales & Continuous Improvement

- Collect client feedback on fit, finish, and function.

- Provide after-sales support for reorders or modifications.

- Update production data to improve future customization efficiency.

Stamping — High-Efficiency Shearing, Forming & High-Repeatability Metalworking Process

Stamping utilizes a press machine combined with precision-engineered dies to apply instantaneous high tonnage to metal sheets. Under this controlled force, the material undergoes operations such as blanking, punching, bending, embossing, and shallow forming.

This process enables rapid, continuous production with consistent dimensional accuracy, making it ideal for medium- to high-volume manufacturing.

Key technical advantages include:

- High Repeatability: Fixed tooling ensures stable dimensions and consistent quality across large batches.

- High Production Speed: Capable of producing multiple parts per minute, significantly increasing throughput.

- Versatile Forming Capabilities: Supports cutting, bending, perforating, embossing, and shallow-draw shaping.

- Cost Efficiency: Highly suitable for mass production, drastically reducing unit cost.

- Excellent Material Utilization: Compatible with continuous strip feeding and automated production lines.

Stamping is widely applied in stainless-steel household hardware, appliance housings, automotive and motorcycle parts, mechanical components, kitchen and bathroom accessories, decorative panels, and various precision metal parts.

Bending / Press Brake Forming — Precision Angle Control & Structural Reinforcement Metal Forming Process

Press brake forming applies concentrated linear force through an upper punch and a V- or U-shaped die to induce controlled plastic deformation along a defined bend line. By adjusting key parameters—such as tonnage, bend radius, die opening, back-gauge positioning, and stroke depth—the metal sheet can be formed into precise angles, flanges, channels, box shapes, and complex geometries.

This process offers several technical advantages:

- High Angle Precision: Capable of maintaining ±0.5° to ±1° accuracy for demanding industrial applications.

- Minimal Deformation: Extremely small heat-affected zone (HAZ), preserving material strength and surface quality.

- Multi-stage Bending Capability: Ideal for fabricating frames, enclosures, brackets, boxed components, and structural parts.

- Wide Material Compatibility: Suitable for stainless steel, carbon steel, aluminum, copper, and other sheet metals.

Press brake forming is widely used in stainless-steel bathroom and kitchen hardware, cabinet structures, electronic housings, HVAC ducting, decorative metal panels, and industrial components requiring high structural integrity and dimensional accuracy.

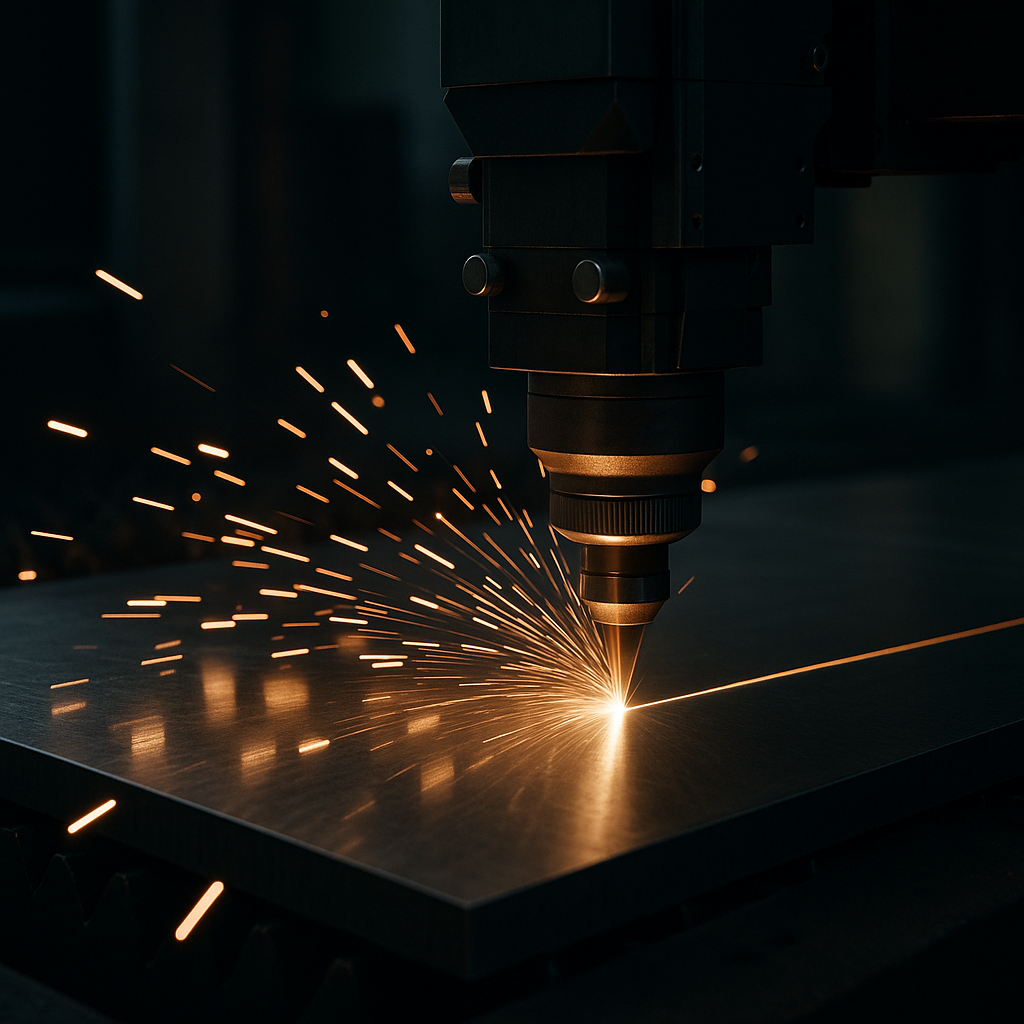

Laser Cutting — High-Energy Melting & Precision Metal Processing Technology

Laser cutting utilizes a high-power, focused laser beam to rapidly heat metal to its melting or vaporization point. With the assistance of high-velocity gases—such as nitrogen, oxygen, or compressed air—the molten material is expelled from the kerf, producing a narrow cut line and exceptionally smooth edges.

This process is characterized by high speed, extreme precision, and a minimal heat-affected zone (HAZ), significantly reducing deformation of the material. Laser cutting is ideal for complex geometries, fine patterns, lettering, decorative perforations, mechanical components, and metal products requiring superior aesthetic quality.

Throughout the operation, key parameters—including laser power, focal position, cutting speed, and gas selection—are precisely controlled to ensure optimal edge quality, verticality, and dimensional accuracy.

Laser cutting is widely applied in stainless-steel modules, mechanical structures, kitchen and bathroom hardware, decorative panels, electronic components, and a variety of precision metal products.

Deep Drawing — High-Precision Metal Forming & Seamless Shaping Process

Deep drawing is a high-precision metal-forming technique that uses a punch and hardened steel dies to apply controlled compressive and tensile forces to a sheet of metal. Under this combined pressure, the material flows into the die cavity and is stretched downward, forming a deep, seamless shape.

This process eliminates the need for welding, resulting in components with superior structural integrity, enhanced airtightness, higher corrosion resistance, and a cleaner aesthetic appearance.

During deep drawing, critical parameters—including lubrication, blank-holder force, material thickness, and metal ductility—must be precisely controlled to prevent defects such as wrinkling, cracking, or uneven wall thickness.

Deep drawing is widely used for stainless-steel kitchen and bathroom products, automotive and motorcycle components, electronic housings, containers, and any metal parts requiring a seamless structure with high durability and precise dimensional accuracy.

Sandblast – Surface Conditioning & Adhesion Optimization Process

Sandblasting is a surface-conditioning technique that uses high-velocity abrasive media to physically impact the stainless-steel surface. This process removes oil residue, oxidation scale, heat-tint discoloration, and minor surface defects, while simultaneously creating a uniform micro-roughened texture.

This controlled micro-texture enhances mechanical bonding and significantly improves adhesion for subsequent processes such as welding, painting, powder coating, electroplating, and PVD coating.

After sandblasting, the metal surface exhibits a consistent matte appearance with reduced glare and minimal fingerprint retention, improving both corrosion resistance and the overall visual quality of the final product.

As a critical pre-treatment step in high-end stainless-steel manufacturing, sandblasting ensures stable performance, improved coating durability, and superior surface uniformity.

TIG welding is one of our core stainless-steel fabrication technologies.

With stable arc control and argon-shielded protection, we produce ultra-clean, fine weld lines with minimal distortion and zero spatter.

This technique is ideal for premium stainless-steel products, including bath fixtures, kitchen hardware, outdoor equipment, sports accessories, and custom metal structures.

Our TIG Welding Advantages:

Ideal for high-aesthetic metal parts that require flawless appearance

Exceptionally clean and consistent weld finish

High structural strength with superior corrosion resistance

Precise heat input control, perfect for thin stainless sheets

Polishing — High-Precision Surface Finishing & Metal Gloss Enhancement Process

Polishing is a multi-stage surface refinement process that uses abrasive wheels, flap wheels, non-woven nylon wheels, and polishing compounds to progressively reduce surface roughness (Ra) and eliminate surface defects.

Through controlled abrasion, the process removes weld marks, tooling lines, oxidation stains, micro-scratches, and burrs while producing a smooth, defect-free surface.

Depending on the required finish, polishing can achieve:

- Mirror Finish — highly reflective, bright, and flawless.

- Hairline Finish — uniform directional grain for a premium brushed-metal effect.

- Matte Finish — soft, non-reflective surface with consistent texture.

Key process controls include:

- Abrasive Sequence Management (e.g., #120 → #240 → #400 → #800 → #1200 → buffing)

- Pressure & Speed Optimization to prevent overheating, discoloration, or waviness

- Consistency Control to maintain uniform grain direction and gloss level

- Material Compatibility across stainless steel, aluminum, brass, and composite metals

Polishing is widely used in stainless-steel kitchen and bathroom hardware, metal appliances, 3C housings, decorative panels, premium consumer products, and industrial components requiring high appearance quality and smooth surface performance.

PVD (Physical Vapor Deposition) is a high-vacuum coating process that vaporizes metal or alloy materials and deposits them onto the product surface, forming a dense protective layer.

The coating provides excellent hardness, wear resistance, corrosion protection, and an elegant metallic appearance, while maintaining the natural texture of stainless steel.

Common finishes include gold, black titanium, rose gold, and silver gray.

PVD is eco-friendly, durable, and strongly adherent, making it ideal for bathroom hardware, architectural decoration, home products, sports accessories, and premium stainless steel items.